Textile reinforced concrete is a new composite material consisting of a textile reinforcement made of carbon or alkali resistant glass and a mineral concrete matrix. Since the reinforcing materials do not corrode, a massive concrete covering, as it is needed with steel reinforced concrete, is not necessary. Concrete components can thus be made much slimmer and lighter. Textile reinforced concrete is currently used for the reinforcement of bridge structures, ceilings, shell constructions and facade elements. To show the potentials of Carbon Concrete, ai:L Leipzig worked in 7 parallel projects:

- C³INFRALIGHT: Functionally layered building shells from Infralight Concrete

- C³SANDWICH: Insulated 3-dimensionally shaped sandwich elements from Carbon Concrete

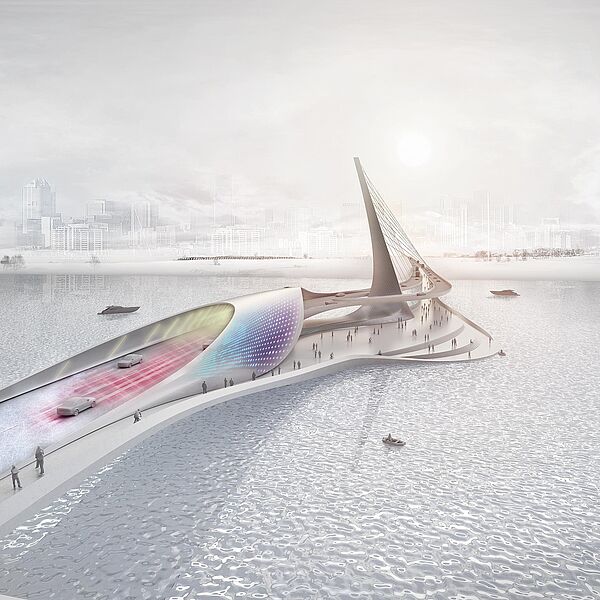

- C³PV: Integration of photovoltaics into Carbon Concrete building elements

- C³SUPERCON: Electrical batteries as part of Carbon Concrete building shells

- C³DAYLIGHT: Translucent insulated Carbon Concrete building shells

- C³LED: Integration of LEDs in Carbon Concrete building elements

- C³SENSE: Integration of sensors in Carbon Concrete building elements

- C³LINK: Synergetical cross-linking of the sub-projects of Base Project 4

In the project, the potentials of carbon reinforced concrete (Carbon Concrete) as a multifunctional building envelope were investigated. The aim was to integrate building functions into Carbon Concrete, thus creating multifunctional components that allow to reduce the building infrastructure and with that the use of resources for the construction and operation of buildings. Together with 20 partners, the ai:L explored different, highly interesting approaches for functional fusions in exposed concrete components that are shortly described below:

C³INFRALIGHT

In C³INFRALIGHT, different solutions for the realisation of layered Infralight Concrete (ILC) components were developed: Firstly as semi-finished, fine grained concrete elements which are finished during construction at the building site. Secondly with a layer-separating, 3-dimensional reinforcement textile, which allows to realize free formed components with layered ILC. Also, material characteristics were determined in building physical tests in order to characterize the new material. Eventually, 3 prototypes were designed and produced that illustrated the advantages of the ILC as well as various reinforcement concepts in carbon and basalt.

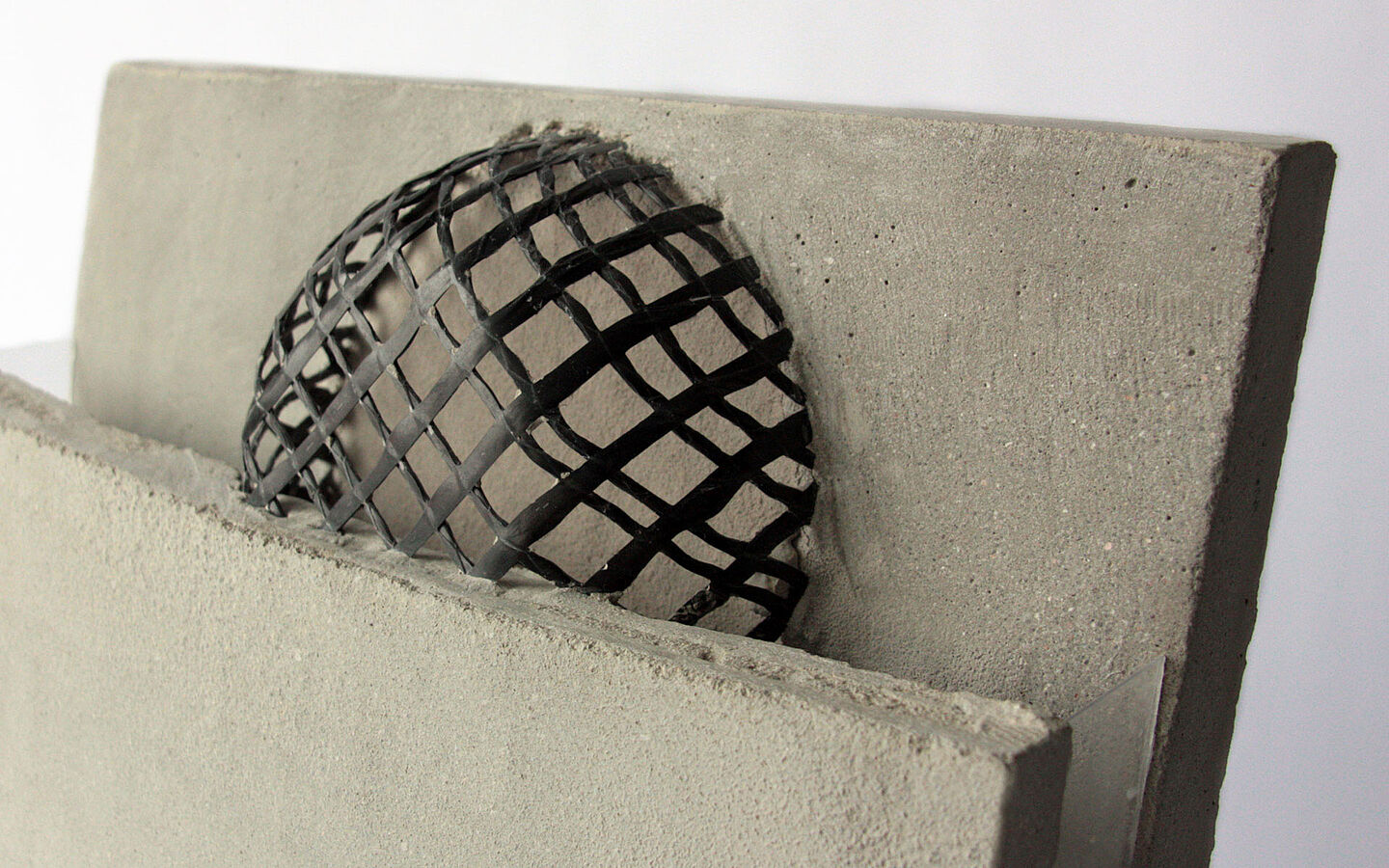

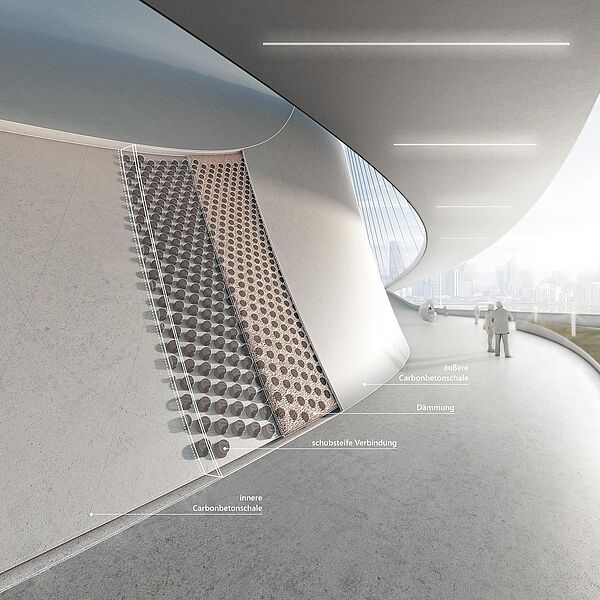

C³SANDWICH

For the development of 3-dimensionally shaped insulated sandwich elements, various natural curving and folding principles were used in the C³SANDWICH and converted into facade designs. Together with the project partners, different reinforcement concepts for the load bearing connection of the outer concrete layers were developed and load tests were carried out, for which the ai:L designed and manufactured suitable test specimens. Another focus was the investigation of possible applications of basalt within the sandwich construction, which can be an alternative to carbon and AR-glass.

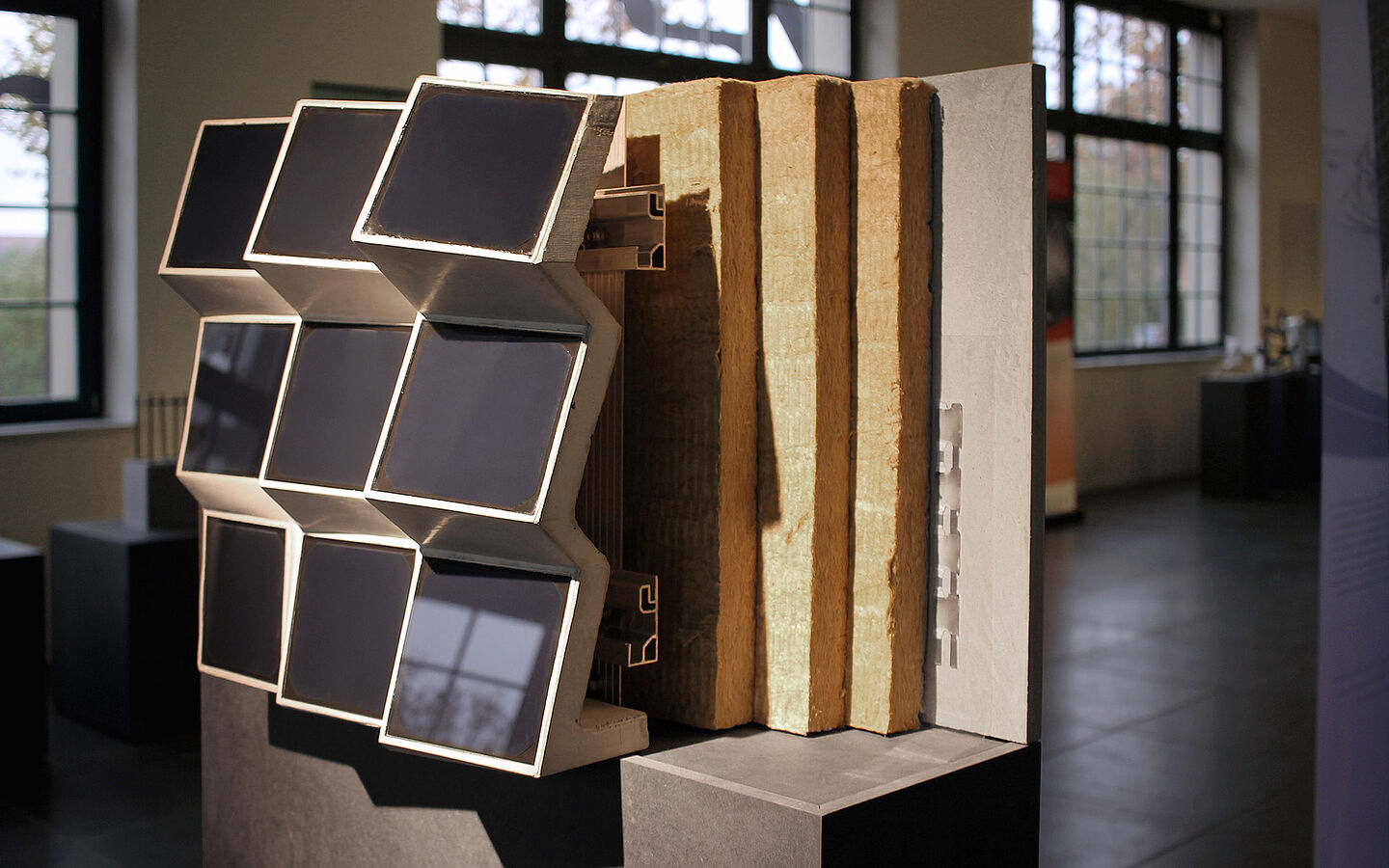

C³PV

In the C³PV project, various solutions for an aesthetic combination of PV-components and concrete were developed and realized in small scale as well as an exemplary system structure. With the aid of parametrically generative design tools, different facade designs have been developed, which align the integrated photovoltaic components in the optimum position to the sun. With that the yield per square meter of PV module can significantly be increased. Together with the partners, 4 different prototypes were planned and realized, which illustrate the developed range of solutions.

C³SUPERCON

In C³SUPERCON, the partners defined application areas and the resulting requirements for building integrated energy storage and quantified the needed storage capacity using a reference building. Also, different principles for integrating the storages into the building envelope could be worked out. Since the storage systems based on films and fabrics had not been technically mature at that time, the structure of the building envelope as well as storage concepts were developed on overview. Finally, 2 prototypes were planned and realized, that introduce the different storage technologies pursued.

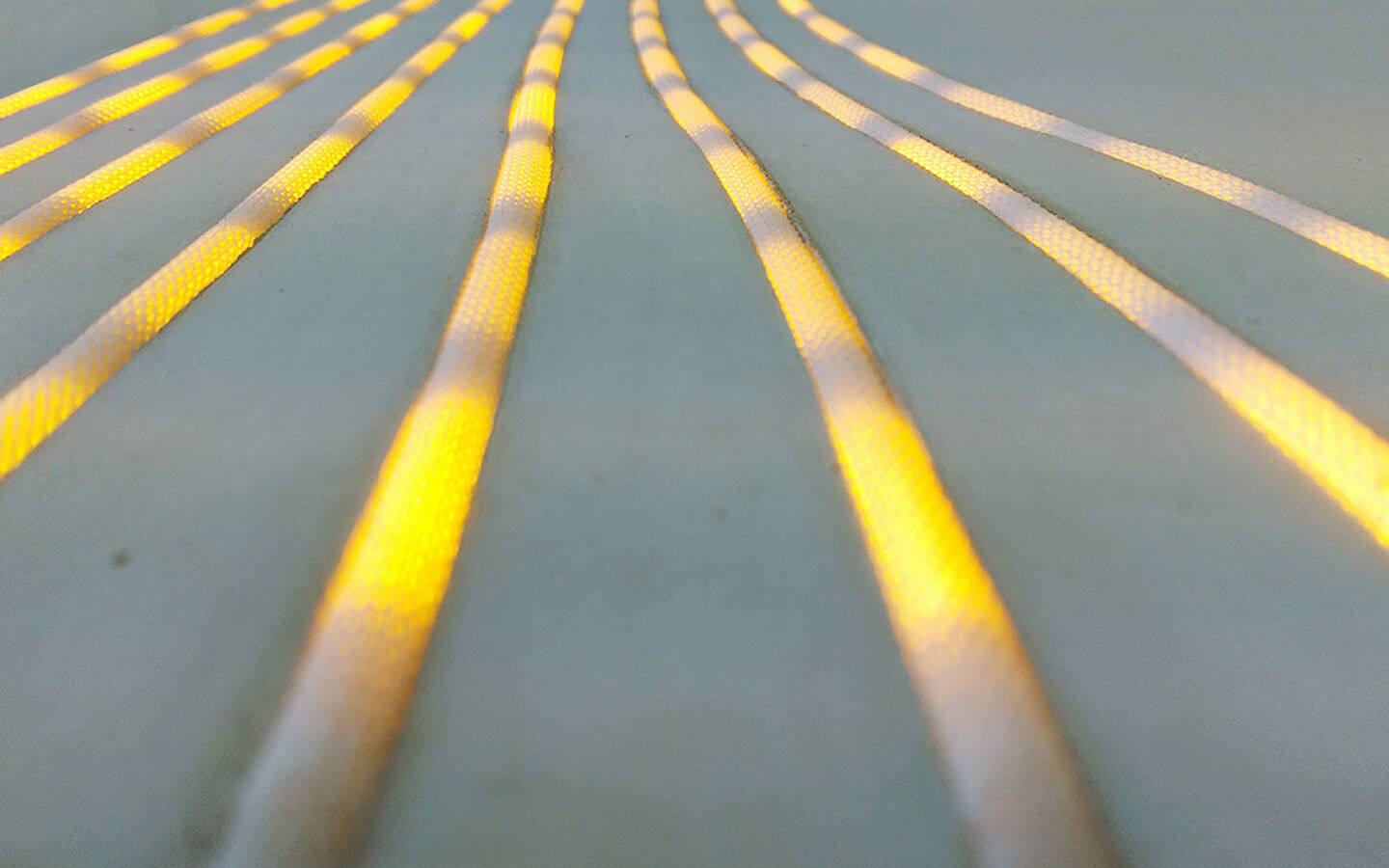

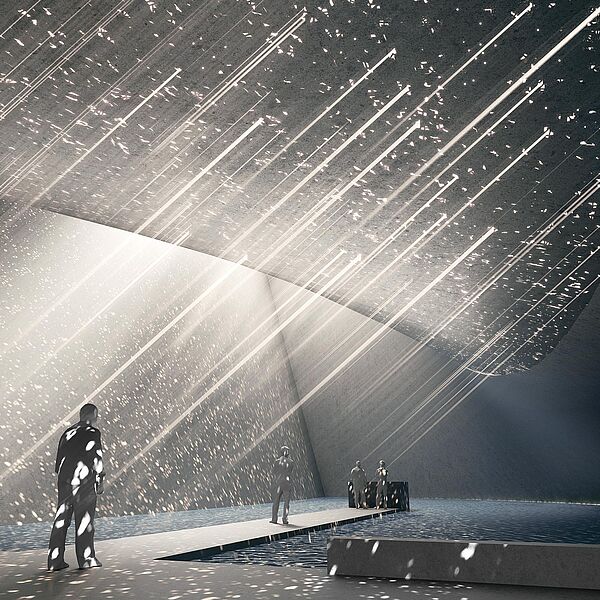

C³DAYLIGHT

In the C³DAYLIGHT-project a slim, heat-insulated and translucent concrete sandwich with integrated light conducting fibres was designed. For its realization, the two solutions "woven 3D textile with integrated light conducting fibres" (preferred option) and "rigid insulating core with inserted light conducting fibres" were developed and examined in models. Concerning the distribution of light conducting fibres on the concrete surface, a digital script was created, which allows to vary the design of the elements by changing variables such as axis distances or fibre radii. Eventually, several prototypes with interwoven light conducting fibres and insulated cores were realized.

C³LED

In C³LED, an architecturally high-grade integration of LEDs into carbon concrete components has been pursued. The aim was to reproduce static and dynamic information in real-time and thus activate building envelopes for additional functions, e. g. signage. For this research approach, various revisable and non-revisable combination principles for LEDs and concrete had been formulated and an exemplary system design as well as utilization concepts could be developed. Finally, 5 prototypes were planned and realized, that impressively demonstrate the diverse developed solutions.

C³LINK

C³LINK carried out the contents als well as the organisational management of the Basic Project 4 and lead the networking of its sub-projects. For this purpose, a comprehensive electrical engineering, a control system for all building elements with additional electrical function and a common prototype of C³LED, C³SuperCon and C³PV were designed and realized. The protection of intellectual property was another important subject area for which the Institute cooperated with patent attorneys. In order to be able to classify the new functional integrations ecologically, an ecological evaluation was carried out.